How to care for my electric tender motor?

Are you a boat owner looking for a quieter, greener solution for your tender? Have you ever considered an electric outboard motor? Our guide will help you maintain your electric motor and get the most out of it.

We’ll cover the essential points for maintaining your electric tender motor:

- Battery: how to check the battery connections and keep it in good condition.

- Propeller: how to maintain the propeller shaft and other related components.

- Anode: how to inspect and replace the anode to protect your engine from corrosion.

- Motor mounting: how to check and adjust mounting bolts to prevent damage.

- Cabling: a few tips on how to store and adjust cables properly.

- Cleaning the motor: tips for cleaning and rinsing your motor after each use.

- Long-term storage: steps to follow to prepare your motor for long-term storage.

By following these tips, you’ll be able to take good care of your electric motor and get the most out of your sailing.

The battery

Battery connections

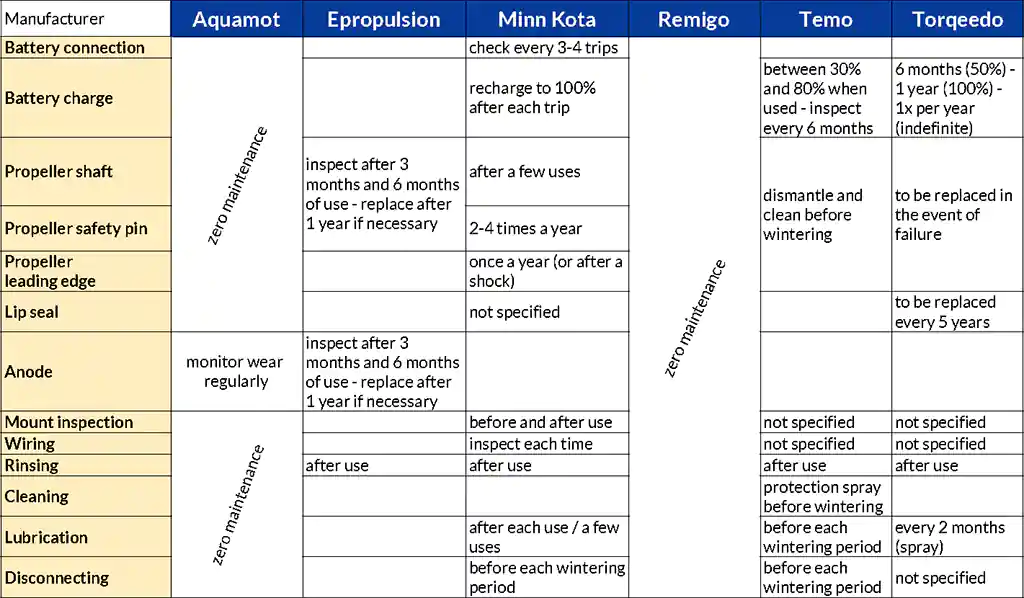

A poorly connected battery can cause the motor to malfunction. It is therefore advisable to check the tightness of the connections regularly. This is an opportunity to check that there is no corrosion on the terminals and wires.

You can clean the connectors with fine sandpaper or a cloth. Sometimes you may need to replace the wires if they are corroded. To prevent corrosion, silicone grease can be your friend. It is often used as a temporary lubricant for joints or polished interconnections, as well as protecting against rust. So remember to apply some after a few trips.

Charging

Since the battery is essential to the electric motor, determine how best to recharge it.

As with all good electrical equipment that has a battery, you need to monitor its charge regularly. Proper care and adherence to the manufacturer’s instructions will prolong the life of the battery and therefore the life of your tender’s electric motor.

Depending on the manufacturer, there are two schools of thought when it comes to charging the battery. Some manufacturers advise you to recharge your battery to 100% after each use. This is certainly the way to ensure maximum range for your next tender trip. On the other hand, others insist that your battery’s lifespan will be maximised by maintaining a charge that is neither too low nor too high, at around 50%. It all depends on whether you want to maximise your range or the life cycle of your battery.

If you need to store your electric motor for a long time, make sure that the battery charge is optimal to allow for natural discharge over time. For example, for a winter storage period lasting a maximum of 6 months, it would be best to leave your battery at 50% charge. For a longer period, it will need to be fully charged before wintering.

The propeller

Propeller shaft

The propeller is exposed to a number of debris that can prevent it from properly rotating. This could be caused by a snagged fishing line or seaweed, for example. An accumulation of debris could damage the shaft seal. Removing any debris caught by the propeller is essential for the longevity of your electric motor.

In general, you can dismantle the propeller after a few uses to check that there is no debris. Some manufacturers recommend less frequent checks as a selling point. For example, some manufacturers will only require you to inspect your propeller only every 3 months.

Replacement may be necessary after a year’s use, in the event of particularly severe wear, but this is very rare.

Propeller pins

The propeller pin can bend. A simple visual inspection can’t hurt, so we advise you to do this regularly whatever your motor’s make and model.

Propeller leading edges

The leading edge of the propeller can be damaged when hitting floating objects. Lightly sanding the blades with very fine sandpaper can be a good practice for optimum maintenance. This check should be carried out after a shock or at least once a year.

The anodes

Inspecting anodes

Sacrificial anodes are designed to protect the metal parts of your electric motor against galvanic corrosion. Regular inspection will enable you to detect signs of wear or deterioration.

Cleaning anodes

If the anode is covered in dirt, mineral deposits or any other type of contamination, clean it carefully with a wire brush or fine sandpaper to remove any build-up and restore its functionality.

Replacing anodes

Inspecting the anode will reveal its condition. When it is more than half worn, it is time to replace it. Failure to replace a worn anode may result in inadequate protection against corrosion and, ultimately, damage to the electric motor’s metal components.

Fitting anodes

Make sure that the sacrificial anode is correctly fitted to the electric motor. An incorrectly positioned or loose anode may not offer adequate protection: it must be in full contact with the metal components to protect your motor from corrosion. Otherwise, the lifespan of your motor will be reduced.

Checking the fastening

Tightening the mounting bolts

When you’re out on your boat, waves can be a source of considerable jolting. The vibrations they cause can loosen the mounting bolts on your engine. If the motor is no longer held properly, it could suffer serious damage. To avoid this, check that the mounting bolts are tight before and after each use, and make sure that any stabiliser bar is secure.

Cabling

Tidying cables

Cables can get tangled. Use zip ties and/or stretch braided sleeving to store and secure cables near your electric outboard motor. This prevents them from getting trapped inside the bracket or being pinched or cut.

Adjusting steering cable tension

In general, the tension of the steering cable is preset at the factory, but it may need to be adjusted from time to time to ensure responsiveness when changing direction. The cable tension adjustment screw may be located under the steering cable cover. For some models, you will need to turn this screw clockwise to increase the tension and anticlockwise to decrease the tension.

In any case, this inspection should only be carried out if you suspect that the cable tension is the source of a problem you have identified. We recommend that you check with your manufacturer before carrying out any work, to avoid aggravating any problem.

Cleaning the motor

Rinsing

Dirt and salt accumulate in the nooks and crannies of your motor every time you go out. For electric outboard motors, most manufacturers recommend that you rinse the entire motor with fresh water after each use.

Cleaning

Clean the motor with water and a mild soap solution. Lubricate the motor shaft by applying a little lubricant such as WD40, then wipe the motor shaft dry with a soft cloth. The best way to preserve your electric motor is to apply a protective spray before each winter. It will prevent dust and particles from accumulating.

Prolonged storage

Lubricating the motor

Before storing your electric outboard motor for an extended period, make sure it is properly lubricated. As with the battery, apply a generous amount of silicone grease to the various terminals on your electric motor.

Unplugging

It may seem logical, but before storing your electric tender motor for any length of time, you should disconnect the battery from its power source. However, some brands offer an intelligent on-board battery charger. This will maintain the optimum charge of the battery during storage.

Summing up

As you’ve seen, maintaining your electric outboard motor isn’t that complicated. But there are a few things you need to do to prolong its life and get the most out of it. You now have all the keys to looking after your electric motor, from the battery to the propeller, via the anode, the wiring and the motor mount. Also, do remember the importance of cleaning and long-term storage precautions.

By carrying out the recommended regular checks and maintenance, you’ll be able to keep your electric motor running for longer and preserve its performance. You can now enjoy your sailing with complete peace of mind. Fair winds and happy boating!