The right moves towards a reliable windlass

Did you know that the tension in a mooring line can run into the hundreds of kilos? For larger boats, even tons can be exerted on the chain when wind and waves get into the mix!

Imagine, then, if instead of manually lifting the anchor on a small boat in a few meters of water on a windless day, you had to do it in other conditions: impossible! Hence the term “weighing” anchor… That’s why many boats are equipped with windlasses – winches dedicated to anchoring. They play a vital role in boat safety, and their maintenance is essential.

We’ll take you through the essential steps to ensure your windlass remains reliable. A few tried-and-tested techniques for cleaning, lubricating and even operating your windlass will ensure its long life. Are you ready to tackle the issue?

The various types of windlass

There are different types of windlasses, each with different requirements. The maintenance they require may also differ slightly. When choosing a windlass, make sure it is designed to match your boat and mooring line. Its hauling capacity must be at least 3 times the weight of the entire tackle gear, i.e. your anchor and chain. In addition, make sure your gypsy or wildcat is well adapted to your anchor chain. It’s the chainwheel that handles the chain. Its dimensions should closely match that of your chain pitch. A case in point : a European-sized gypsy will not fit an American chain, and vice versa.

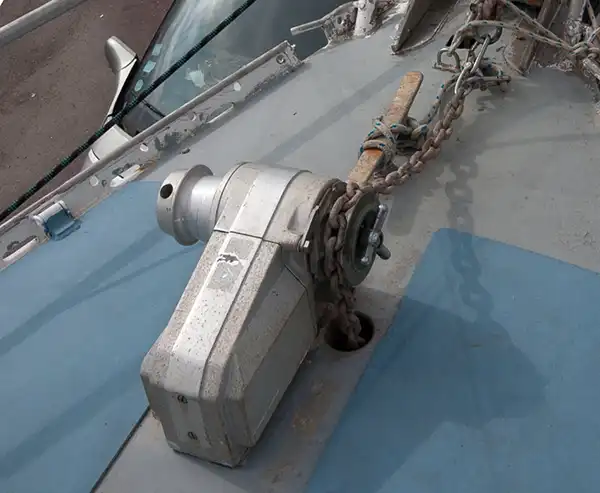

Few leisure boats are equipped with two windlasses like this one. When there’s only one on board, it’s crucial that it works! This means caring for it so that it’s there when you need it.

Vertical or horizontal axis?

First determine whether your windlass has a vertical or horizontal axis. If you’re installing a new one, consider the space available on deck and in the chain locker. If you want your windlass to be as unobtrusive as possible, and you have enough space in the chain locker, a vertical-axis windlass is best because the motor and gearbox is located below-deck. In this case, it’s technically called a capstan, but for the sake of clarity, we’ll continue talking about windlasses for both types. Horizontal axis windlasses are more suitable for smaller chain lockers, since they are positioned above-deck, unlike vertical axis designs.

Manual or electric windlass?

You also need to choose between a manual or electric windlass. With a manual windlass, you haul in the anchor using a handle. But this takes a lot of time and effort.

If you choose an electric windlass, you’ll need a battery or an electric recharging system. It’s best to install the battery close to the windlass to avoid having too long a cable between the battery and your windlass.

And lastly, when using an electric windlass, be sure to have your engine running when you haul in the anchor. This ensures that your battery is supported by the engine’s alternator. Failing this, you risk damaging your battery and electrical cables, because the power required can be so great (we’re talking tens if not hundreds of amps!).

A manual system will obviously be more painstaking, but electric windlasses consume a lot of energy. What’s more, if your electrical system fails, you’ll have to wind up your mooring line manually anyway. The choice is yours!

Inspect it every time you go out

To ensure that your windlass lasts and doesn’t jam while you’re out on the water, remember to give it some love after every trip. The first step in caring for your windlass is simple: rinse it thoroughly with fresh water to remove salt and prevent corrosion. Next, you can check the seals to make sure they’re in good condition. It’s imperative that no water makes its way into the windlass.

Depending on your windlass model, it may need topping up the oil from time to time. If so, check the oil level regularly. You can monitor the level through an eyecup. Or it may just need lubrication. In that case, grease it from time to time.

On electric windlasses, inspect the electrical connections from time to time, and check that the remote control or button is working properly. If you’re going on a trip where you’ll be getting wet on a regular basis, make sure you do this before you set off! And don’t forget to check that the fuse is also working properly.

For electric windlasses, inspect the electrical connections once in a while, and make sure the remote control or switch is working properly. If you’re going on a trip where you’ll be dropping anchor regularly, make sure you do this before you set off! And don’t forget to check that the fuse hasn’t blown.

Servicing your windlass

We recommend that you carry out a complete windlass service once a season. For this maintenance, whatever your windlass, first open the cover so you can clean and grease the gears. To make maintenance easier, you can disconnect your windlass from the deck. Then, if you have any doubts about the gaskets around your windlass, replace them! Better safe than sorry.

A windlass is made up of several components: the gypsy (or wildcat), the warping drum, the gearbox, the housing and, if necessary, the motor. Remove the windlass chainwheel to access the inside, and then clean and lubricate the gearbox. Check the condition of the gypsy for signs of corrosion and mechanical wear (it can lead to chain links skipping). Once everything is in order, you can reassemble it.

Some parts may be worn, and you can replace some of them. Turn to your dealer for spare parts suitable for your windlass. Or you can look in the instruction manual for information on specific components. On electric windlasses, for example, the motor brushes often wear out after several years and can be replaced.

In the case of electric windlasses, you need to avoid corrosion and water in the motor terminals and electrical components. To do this, you can treat the terminals with an anti-corrosion spray.

For windlasses requiring an oil sump, be sure to change the oil. You can ask the manufacturer or look in the instructions for the type and quantity to use.

Take the strain off your windlass

When you’re out on the water and dropping or hauling the anchor, it’s possible to take the load off your windlass with a few simple tricks. It will thank you for it by lasting much longer.

Once anchored, you can remove the tension from the mooring line off of your windlass by using a snubber. A gripper hooks onto the chain, while at the other end, the bridle is tied to the bow cleats. Mooring tension and anchoring shock loads are then absorbed by the line and transferred to the bow instead of the windlass. Oh, and now your snubber is in place, and before you turn off your engine, remember to do a good hard reverse to make sure your anchor has firmly hooked to the ground.

It’s also a good idea to reduce the tension on your windlass as you weigh anchor. To do this, use your engine and move closer to your anchor. During this maneuver, the windlass simply takes up the slack in the chain. It is not the windlass’s job to bring the boat closer to the anchor. It only really starts pulling when the anchor is vertical to your bow.

Ready your windlass!

Whether your windlass is horizontal or vertical, manual or electric, taking good care of it means avoiding unpleasant surprises on your next adventures.

We’ve seen you need to rinse it regularly while protecting it from water ingress. Servicing it is mainly cleaning and lubricating mechanical parts, and protecting electrical connections if applicable. Maintenance once a year is a good way to go. Ready4Sea is here to help: when you add your windlass to your boat app, we’ll suggest the typical maintenance reminders. You’re free to adjust the frequency and/or dates later. How convenient!